MIG and TIG Welding

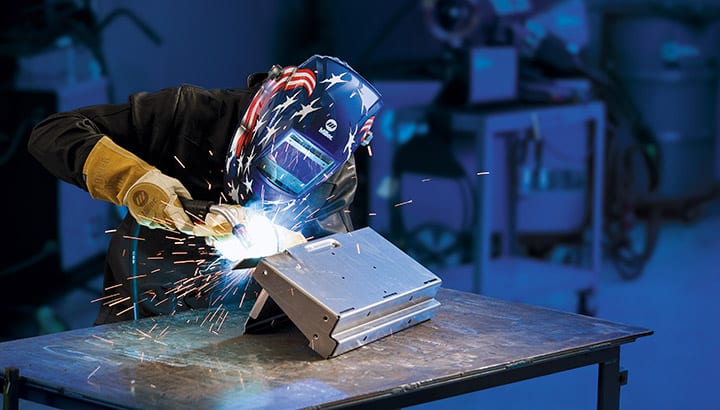

The Art and Science of Welding

Troy Laser & Fab incorporates the most advanced MIG & TIG welding technologies and techniques available today. Our state-of-the-art welding tools and premium MIG and TIG welding services combined with the utmost precision and accuracy for creative and effective designs pushes the limit of current manufacturing standards and ensures every output is well-balanced and at its best quality.

MIG Welding

We can manually weld all steel, aluminum and other stainless steel materials and alloys by utilizing MIG welding. Benefits for the MIG Welding process include:

- High productivity

- Minimum cleanup

- Higher deposition rates

- All-position welding capability

- Ability to weld sheet metals into all positions

- Capability to join a wide range of metals and thicknesses

- Long welding projects can be carried out without interruption

TIG Welding

The TIG Welding process is versatile when it comes to different metals and produces the highest quality weld and is utilized for welding metals other than common steel, critical weld joints and for when precise, small welds are needed. TIG Welding methods offer many different advantages including:

- Superior quality

- Free of spatter

- Low distortion

- Variables can be precisely controlled

- Can be carried out with or without fillers